Making the best possible growing mix requires uniformly combining top quality components. They must work together to provide a structure that effectively manages applied resources and promotes beneficial microbial development. The mix must be free of contaminants and deliver the best physical, chemical, and biological properties for the life of a crop. Today, responsible growers use blends that provide for a more sustainable production system. Advancements are focusing on the use of recycled and renewable materials to build high performing growing substrates. PittMoss LLC is leading the way in using organic recycled materials specifically engineered for peak performance and sustainable crop production.

Properties Vs Components

If you work hard enough, it is possible to grow in nearly any mix, however, you must use the right methods and make significant adjustments to match a particular mix. It is the goal in growing substrate formulation to provide properties that support the best development with the most effective and efficient management. In order to achieve this, the properties of the final blend must include a stable physical structure that provides good water holding capacity while maintaining sufficient aeration for gas exchange (breathing) to the roots. It must hold and deliver nutrients at an ample quantity and rate while supporting microbial activity.

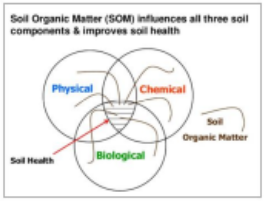

Components are blended to produce the best properties. By balancing the components, the properties of the final mix will support rapid crop growth while remaining free of toxins and environmental contaminants. By selecting the proper components and blending them together at the best ratio, optimal properties can be built into the mix. Various types and ratios of components provide different characteristics that can serve to build in the best properties. The physical, chemical, and biological properties of PittMoss make it an effective component to improve nearly all blends.

Goals for an Optimal Substrate

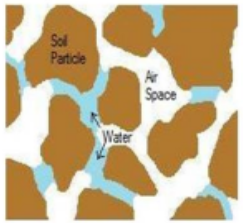

The density (weight per volume) should be high enough to hold the plants upright and low enough to provide easy handling of growing containers. Typically, a dry blend in the range of 7 to 14 pounds per cubic foot (0.075 to 0.15 g/cc) is desirable. A good balance of large and small pores provides the best ratio of air infiltration and water holding. Large pores provide for aeration and should occupy from 8 to 16 percent of the space. Fine and very fine pores, on the surface and within the components, provide water holding. The saturated total porosity (air and water holding) should range from 60 to 80 percent of the space. The pH level should range from 5.5 to 6.8 for most crops. The total soluble salts should range from 0.75 to 3.5 mS/cm in a saturated media analysis, or about 0.4 to 1.7mS/cm in an analysis using two volumes of water to one volume of the substrate.

Nutrients should be balanced to match the crop’s specific requirements. The absence of toxic levels of sodium, boron, ammonium, and heavy metals is essential. Readily available (labile) carbon should be present to provide food for microbial life. High nutrient buffering (or adsorption) reduces nutrient runoff, therefore lowering costs to growers while at the same time being environmentally responsible. The high surface area and sequestering ability in low density PittMoss provides soil structure made from organic matter in a form that makes it the most sustainable while saving on fertilizer and providing ease of management.

Critical Characteristics of Components

Each media component has unique physical characteristics that impact the blend’s particle size, shape, and resilience. Field soil, dusty peat, fine-textured components, or additives with weak structure can reduce total pore space by filling in the larger pores. Small, very fine, rounded particles intermix and fill in larger pores, thus reducing total pore space, aeration, and water holding capacity. When considering the chemical or nutritional properties, the acidity and alkalinity of a component is crucial. The mineral content of components can significantly alter the pH as well as the soluble salts (EC), thereby influencing the final balance of nutrients. PittMoss, perlite, vermiculite and sphagnum peat are low in soluble minerals, while compost, manures, biochar, worm castings and many additives can be high in minerals and may carry toxic elements.

Cation exchange capacity (CEC) is commonly referred to when considering the ability of a media to buffer nutrients. In container growing substrates, however, CEC is less significant than the adsorptive and sequestering ability of the components. CEC is based on cations held loosely bonded to the components and is measured per unit weight of the component. In growing mixes, we are more concerned with the nutrients held within a unit volume in a container. The high surface area and sequestering ability of PittMoss saves on fertilizer applications and provides easy water management.

Many materials like sphagnum peat, pine bark, and some compost become difficult to moisten when dry (hydrophobic), often requiring the incorporation of wetting agents. The unique properties of PittMoss make it ready to absorb and release water, even in very dry conditions.

Testing individual blend components provides information that helps to predict its effect on a mix. With a thorough understanding of each of the materials incorporated into a mix, blenders can anticipate the potential impact and set appropriate blending ratios.

A critical economic factor is mixing loss of volume. Mix yield volumes are influenced by the nature of the components. Oftentimes, a cubic foot of material will be reduced when the fine particles intermix and sink into voids, plugging pores and reducing the volume yield. Conversely, materials like PittMoss can create a bridging effect due to the shape and form of the particles, increasing air space and water holding capacity while expanding the total volume. With the incorporation of PittMoss in a blend, one can produce total blend expansions as high as 22%.

Impact of Additives

Once the components for making the optimal physical structure are chosen, additional additives are applied to round out the final nutrient package. This can greatly influence the chemistry and biology of the blend. Natural and synthetic components are available to achieve the desired balance. When making living soil blends, reliance on natural components and additives to support microbiological activity is of key significance.

Careful evaluation of the additives and fertilizers is necessary. Success depends on achieving the ideal pH (acidity or alkalinity) needed as well as the specific nutrients desired. Liming with dolomite (containing both calcium and magnesium) or calcite (calcium only) is most often used to increase the pH of the blend. Fine-textured or hydrated lime is often used when fast reactions are needed. PittMoss does not require added lime, and when incorporated as a portion of the blend, PittMoss will reduce the amount of lime required. Sulfur and acidic fertilizers are commonly used to lower substrate pH. To avoid significant failures, it is always advised to test a new mixture after moistening it, followed by storing it at room temperature for about ten days. Many components contribute to the total soluble salts level (EC) and may also contain undesirable minerals. For instance, manures and composts often have elevated levels of sodium, chloride, or ammonium and sea salt. While adding needed micronutrients, manures and composts can sometimes add excess levels of sodium, which at high levels acts as an antagonistic and toxic ion. Always avoid using high ammonium or urea containing fertilizers when using PittMoss. A growing media analysis from a reputable laboratory will help to fully understand the chemical nature of the final blend.

Mixing

Components mix well when slightly moist, so a moderate amount of water should be applied to the components prior to mixing. Avoid over-saturating the components. Carefully measure the volumes of the components by uniformly and lightly compacting them. If hand mixing, distribute the components in thin layers, stacking coarser materials on the bottom and finer components on the top.

Uniformly distribute additives onto the surface of the components rather than distributing the components onto the additives. If using a rotary blender, add the coarser components first, then after a brief mixing, add the finer additives. Mix thoroughly, but do not mix to the point where the components begin to fragment. A good blend will feel spongy and slightly compact when squeezed but will bounce back when released. The blend should form a ball when squeezed, but that ball will crumble easily when prodded. If it sticks together, then it is too wet for handling and filling containers.

Filling Containers

Freshly mixed blends incorporating PittMoss tend to be highly aerated, looser, and lighter than other blends. When using PittMoss-containing mixes, it is important to sufficiently fill the containers by compacting the blend to the desired density. In some applications, this may require some backfilling after initially filling and compacting the material around the plant.

Storage

It is typically best to use a blend that has been freshly made, although a properly stored blend should be usable for up to one year. Keeping your growing substrate in good condition requires avoiding contamination. It is best to select an area under cover, as wind can carry weed seeds and pathogens while wet conditions encourage algae growth and attract fungus gnats. Insects, animals, birds, and pets have also been known to spread and deposit contaminants. Since PittMoss encourages microbial activity, with the incorporation of nutrients, you can expect high rates of biological growth that can produce significant heat in stored piles. Thus, filling containers in advance is advised to avoid the build up of heat. Extended storage can result in a breakdown of particle structure, damaging the aeration and water holding. Additionally, nutrients may mineralize and solubilize, resulting in an increase of soluble salts.

A Better Mix with PittMoss

When incorporating PittMoss into your blends at rates from 20 to 60%, you can expect superior performance. Your growing mix will be more sustainable, increase in volume, provide better aeration and gas exchange, manage resources better, minimize nutrient runoff, reduce watering requirements, and provide a longer shelf life. In the coming years, we will see more of a circular economy in the growing media industry. Mining of peat moss will decrease and sequestering carbon dioxide will increase. To learn more about sustainable growing, you can contact PittMoss LLC through our website, social media, or by emailing info@pittmoss.com.

Leave a reply

You must be logged in to post a comment.