- Our Products

- Store Locator

- About Us

Why Use Pittmoss

- Contact Us

Press

PittMoss in the news

The 13 Best Potting Soils for Indoor and Outdoor Plants

Just like with gardeners, no two gardening projects are alike. That calls for a variety of potting soils and mixes that suit each plant or gardening need.

When shopping for the best potting soil, consider how much you will need, what type of plants you’re growing, and whether the mix includes peat (which isn’t always harvested sustainably). Also consider whether you need fertilizer and, if so, whether you want to avoid synthetics.

To narrow down the list, we researched the best potting soils, taking into account the considerations above along with consumer ratings. We also talked with Evan Davis Santi, a horticulturalist with Urban Plantscapes LLC, and Charlie Nardozzi, a Regional Emmy Award-winning garden author, radio, and TV personality.

The PittMoss Plentiful Organic Potting Mix is our top pick for best overall potting soil because it is peat-free and organic. Plus, it can be used for a variety of gardening needs.

Here are the best potting soils.

- Best Overall: PittMoss Plentiful Organic Potting Mix

- Best Organic: The Sill Organic Potting Mix

- Best Indoor: Good Dirt Indoor Potting Soil Mix

- Best for Raised Beds: Mountain Valley Seed Company Minute Soil Expanding Coconut Coir

- Best Garden Soil: Miracle-Gro Nature’s Care Organic Garden Soil

- Best for Starting Seeds: Hoffman Seed Starter

- Best Orchid Mix: SuperMoss Orchid Bark

- Best for Moisture Control: Miracle-Gro Moisture Control Potting Mix

- Best for Outdoor Plants: Espoma Organic Potting Mix

- Best African Violet Mix: Soil Sunrise African Violet Potting Soil

- Best Peat-Free Soil: PittMoss Performance

- Best for Succulents and Cacti: Perfect Plants Organic Succulent Soil

- Best for Flowers: Proven Winners Premium All Purpose Potting Soil

What We Recommend

Best Overall: PittMoss Plentiful Organic Potting Mix

Why You Should Get It: This all-purpose potting mix includes recycled paper as its growing medium, allowing you to avoid peat moss, which is often harvested unsustainably.

Keep in Mind: Working with the mulch-like recycled paper may take some getting used to.

Our choice for the overall best potting soil, PittMoss’ Plentiful Organic Potting Mix is OMRI (Organic Materials Review Institute) listed, which means it’s been independently reviewed to adhere to organic standards. It’s primarily made of recycled paper products, and while paper isn’t a traditional medium choice for many gardeners, you won’t have to worry about this potting mix containing unsustainably harvested peat moss.

The mix is lighter in weight and isn’t as dusty as some soil blends. It’s also free of weeds, so you won’t have to worry about unwanted plants growing in your planter. The mix contains readily available carbon to promote healthy biology for growing plants, and it requires less fertilizer and watering than other potting soils, saving you time and money.

This is an all-purpose option that can be used for vegetables, indoor plants, raised gardens, and most other types of situations that call for a typical potting soil. It can even be used for grass seeding or for starting seeds. Natural ingredients, like feather meal, are incorporated to boost nutrients.

Product Details:

- Size: 10 quarts, 1 cubic foot, and 2 cubic feet

- Use: All-purpose

- Organic: Yes

Best Organic: The Sill Organic Potting Mix

CREDIT: COURTESY OF THE SILL

Why You Should Get It: It contains coconut coir rather than peat moss. Coco coir has a more neutral pH level, making it a better fit for most plants when compared to the higher acidity of peat moss.

Keep in Mind: This mix is best for indoor plants, so you’ll want to choose a different mix for outdoor gardening.

For the best organic potting soil mix, consider The Sill’s Organic Potting Mix, which is also OMRI listed. It contains just five ingredients: compost, pine bark, coir, worm castings (droppings), and perlite to promote drainage.

This natural, organic mix is best suited for growing healthy indoor plants, so you’ll want to opt for a different type of potting soil if you need to also fill outdoor planters. Choose from a 2.8-pound bag or the larger 8-pound option. The smaller of the two sizes is sufficient for potting up to two medium sized plants or three smaller plants. If you have a lot of plants to repot or if they’re on the larger side, you’ll want to buy the bigger bag.

Product Details:

- Size: 2.8 or 8 pounds

- Use: Indoor plants

- Organic: Yes

Best Indoor: Good Dirt Indoor Potting Soil Mix

CREDIT: COURTESY OF GROVE COLLECTIVE

Why You Should Get It: This option contains sustainably harvested, partially petrified peat moss, making it a more eco-friendly choice than other mixes on the market.

Keep in Mind: Plant food is mixed into this potting soil, so it’s not as easy to customize.

Our choice for the best potting soil for indoor use, this Good Dirt potting mix is specially formulated to help indoor plants grow and is a great choice for those looking for a natural mix that’s free of chemicals and GMOs. It’s also free of animal products and is safe to use around pets and children.

The potting soil uses partially petrified peat moss from sustainably-harvested peat bogs to promote the soil aeration and healthy drainage levels indoor plants need. Plant food is also built into the mixture. While convenient, it may not allow for easy nutrient customization which is something to keep in mind if you’re looking for that option. However, the plant food is organic and features plant probiotics that promote root health.

Product Details:

- Size: 3.8 pounds

- Use: Indoor plants

- Organic: Yes

Best for Raised Beds: Mountain Valley Seed Company Minute Soil Expanding Coconut Coir

CREDIT: COURTESY OF AMAZON

Why You Should Get It: The dehydrated mix is compact and easier to store than bags of potting soil.

Keep in Mind: You’ll need some water on hand to rehydrate this potting soil.

Mountain Valley Seed Company’s Minute Soil Expanding Coconut Coir is made of 100% non-amended coco coir, making it a great choice for gardeners looking to avoid peat moss and those wanting to add their own fertilizer.

This dehydrated mix takes up less storage room and is designed to be used as you would traditional potting soil—just rehydrate it with water before using. We chose this as the best potting soil for raised beds because you can easily place the blocks, bricks, or pellets (depending on the size you choose) right into the garden bed before rehydrating them. You could also rehydrate the potting soil in a wheelbarrow or other container first, if you prefer, to give yourself a bit more control over how much soil you use. Each block, brick, and pellet will expand by 15 times its initial size once rehydrated.

The company offers multiple sizing options, making this a convenient choice for raised beds and containers of varying depths. Coconut coir is used for soil aeration and to increase water retention to promote root health. You may also use this potting soil for starting seeds inside or as a soil for use with outdoor plants. It is OMRI listed.

Product Details:

- Size: Multiple—a wheelbarrow-sized block, bricks, and pellets from 20 to 100 millimeters in diameter

- Use: Multiple but ideal for raised beds

- Organic: Yes

Best Garden Soil: Miracle-Gro Nature’s Care Organic Garden Soil

CREDIT: COURTESY OF THE HOME DEPOT

Why You Should Get It: This option includes plant food for vegetables and flowers that lasts about two months.

Keep in Mind: The potting soil includes bone meal, so it’s not the best choice for people who prefer to avoid animal byproducts.

If you’re planting right into ground and your soil could use a bit of extra nutrients, the Miracle-Gro Nature’s Care Organic Garden Soil is our top pick for the best potting soil for gardening. The mix is an all-purpose selection, meaning it’s designed to be used with a variety of plants. Try it for flowers as well as fruits and vegetables that need to be grown in the ground rather than in a container.

This option is an organic, OMRI-listed pick. It contains coir along with alfalfa meal, bone meal, earthworm castings, and kelp meal to increase the nutrient content. If choosing a vegan option is important to you, keep in mind that this pick contains animal byproducts.

The mix contains enough plant food to last plants for about two months. Make sure to have additional food on hand if you’re growing plants that will need a longer-lasting boost of nutrients.

Product Details:

- Size: 1.5 cubic feet

- Use: Garden soil

- Organic: Yes

Access the full article at bhg.com

Needed or wanted: Substrate extenders, and alternatives

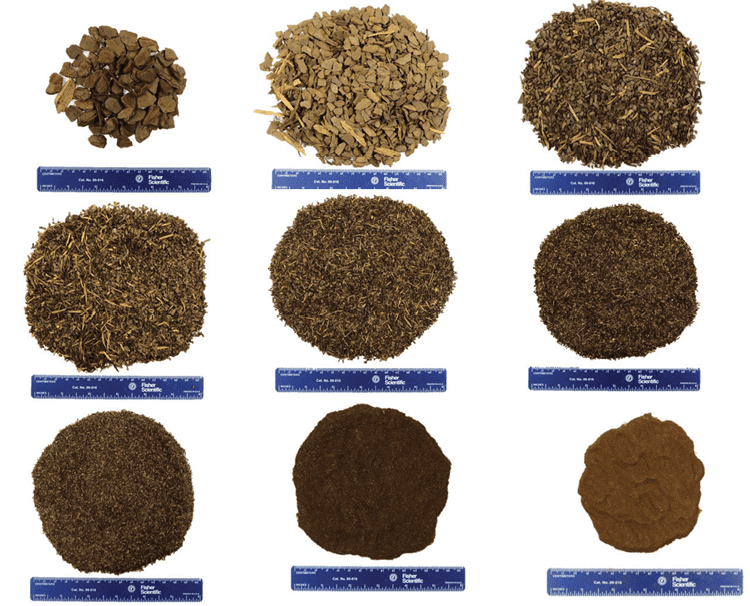

Fig. 1. The ability of bark materials to be easily engineered is one of several reasons for its increased usage in many types of growing media.

Photo credits: All photos were taken by Brian Jackson

Either proactively or reactively, the need for substrate (growing media) options is always important for growers.

Recent shortages have led to many growers being forced or highly encouraged to turn to “Plan B” in their substrate toolbox to bridge the gap between increased demand and some drastic shortages of common growing media components and products.

Many growers have even had to turn to “Plan C” or beyond to acquire the volumes of substrates needed for their rapidly expanding operations. Aside from supply shortages, other consumers have elected to explore new or alterative substrate options based on sustainability beliefs and goals, desire to use local or regional materials, the opportunity to utilize raw materials they already have access to, or to adopt new substrates that are better crafted to better optimize the crops they are growing in the specific growing systems they are utilizing.

Whatever the reason, the interest and demand for non-traditional substrate materials has never been higher, a trend that will only increase exponentially in the future.

This article will discuss some of the materials that are in higher demand and use today based on any or all of the above-mentioned reasons. It is also very important to note that not all possible substitutions or alternatives are listed here, as there are many that warrant attention and consideration.

Lastly, it should be strongly emphasized that there are no “replacements” for any substrate materials, as it is impossible to truly and literally replace something. So, there are no “peat replacements” or “perlite replacements” but instead viable materials that are suitable alternatives or substitutions to certain commonly known (traditional) materials.

Processed bark

While not new or novel in any way, processed bark materials continue to evolve in their usage across many substrate product lines and growing systems (Fig. 1). A material used by growers since the 1960s,bark, particularly aged pine or fir bark, continues to fill the void left behind by peat or coconut (mainly coir) product shortages. Most traditionally used in outdoor ornamental nursery crop production and more recently in soft fruit container production, the use of bark as a an aggregate additive or extender to peat in greenhouse substrates has increased significantly in the past decade. Thanks to advanced and particular processing techniques and handling methods, bark can be processed into a wide range of particle sizes as illustrated in Figure 1. These size fractions can then be combined in any conceivable combination to engineer a substrate with very specific air and water properties, drainage profiles, densities, or structure for long-term container production.

For example, bark can be processed (double processed), fractioned, and reconstituted to have identical air and water porosities has any peat or coir substrate. Couple those abilities with the option of blending other materials with bark, and the options for nursery, greenhouse/floriculture, cannabis, or soft fruit production can be successful, even without traditional peat or coconut coir (excellent materials by the way) if they are unavailable or not desired.

Fig. 2. Biochar product offering and use continues to increase in the growing media industry (A-B) and rice hulls have gained even more interest and utilization as substrate aggregates (C-D).

Biochar additives

Interest remains high for biochar products as additives or substitutes in soilless substrates (Fig. 2A-B).

Perhaps still more of a highly specialized or “novelty” component for many growers, others have trialed or adopted biochar products in some of their operations.

First, it is worthy of discussion that “biochar” can in many justified ways be considered a verb and a noun based on the high variability that can (and does often) exist in commercial products based on manufacturing methods and feedstocks. Similar to compost, biochar products can be extremely variable from source to source and even within a single production source over time. The cost of biochar also remains high in many areas and therefore is often not as economical as other materials.

The availability, consistency, and cost of biochar products is improving, however, and eventually the price and quality will likely be highly predictable and dependable.

As far as uses, despite some report’s, biochar cannot replace peat moss, but it can serve as an adequate substitute for perlite and it can be used as a partial peat or bark substitute or extender if the particle size is suitable/acceptable to the mix it is being added to. The stability that biochar adds to substrates is exceptional (for longer term perennial crops in containers) and most biochars can provide some limited nutrient availability to crops, increased nutrient holding and exchange capacities, and it can also initiate or host beneficial biological/microbial activity in soils and soilless substrates.

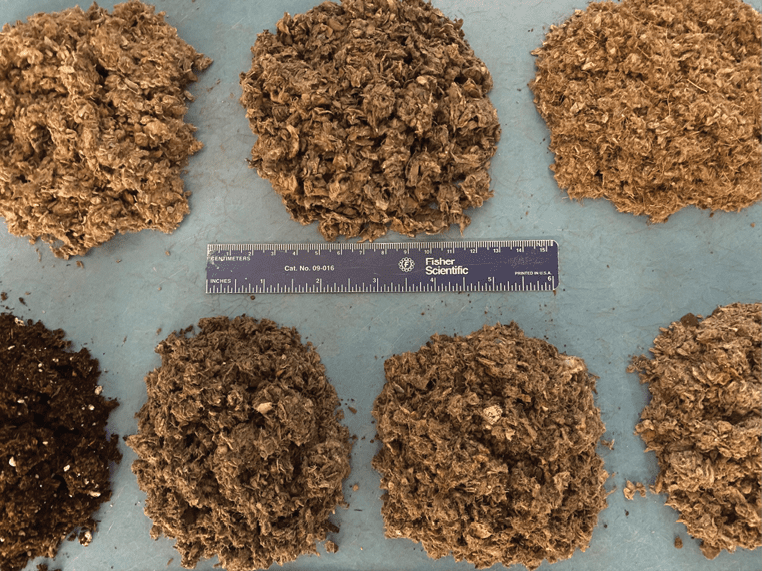

Fig. 3. Pittmoss’ product line has expanded in recent years and now offers growers many choices for various types of crop production.

Photo credits: All photos were taken by Brian Jackson

Rice hulls

Rice hulls have seen a tremendous boost in sales and utilization across the horticulture industry in recent years. Thoroughly developed in the early 2000’s in large part due to research efforts from Dr. Mike Evans at the University of Arkansas (currently at Virginia Tech), rice hulls have been a trusted and viable commercial substrate component for many years.

Investigated as a substrate aggregate (perlite substitute), rice hulls were also discovered to be a highly effect weed barrier when used as a container mulch on outdoor (nursery) crop production. The extreme shortages in the perlite supply chain since 2020 have renewed the interest and use of this material as an aggregate to peat substrates. Available in small and large compressed bales, parboiled rice hulls are a regionally available (Arkansas and the Mississippi delta), organic by-product with large volumes of supply typically available (Fig. 2C-D).

Pittmoss

No stranger to the growing media arena, Pittmoss is a product line (as well as the name of the company and brand) that has been producing growing media components since about 2015. Originally produced from just recycled newspapers and cardboard, today the Pittmoss product line uses other recycled organic/cellulosic materials as well.

No longer a local Pennsylvania and surrounding states product, Pittmoss now has at least seven products available for both professional and retail/hobby markets (Fig. 3). Best when used as an additive or extender to peat moss, coconut coir, aged bark or perhaps even wood fiber, the inherent physical and chemical properties seem to be suitable and beneficial as a mix component. Perhaps a good option for extending peat and coir supplies for short(er) term crop production.

Fig. 4. Miscanthus biomass can be processed in different ways (extruded, disc-refined, and hammer milled) to create unique fibrous materials for potential use as substrate components.

Processed miscanthus

The outlier of the group, processed miscanthus biomass, is appearing more and more on the alternative substrates radar.

Initially investigated well over a decade ago for its potential use as a component in nursery crop production, miscanthus today is being evaluated heavily again for other potential uses.

The availability of miscanthus biomass mostly comes from the large acreage that was planted 10-15 years ago during the early stages of the biofuel revolution when investors, business folks, and growers were planting thousands of acres proactively in hopes that the biomass market (for biofuel production) would explode and be a huge return on investment. While there is still biomass and biofuel research being conducted today, the volume of unutilized miscanthus in the eastern US is extensive.

Based on new processing technologies and material preconditioning treatments, miscanthus grass can be refined in to very fiberous, water absorbing, and low-density substrate components (Fig. 4). The potential for this fiberous material to be a suitable substrate component for short term crop production is increasing.

The author is a Professor of Substrate Science and Director of the Horticultural Substrates Laboratory at NC State University. Brian can be reached at Brian_Jackson@ncsu.edu

https://www.greenhousemag.com/article/growing-media-substrate-alternatives/

GrowCast: Environmental Cost of Peat, Sustainable Grow Media, and More, with Ashley from PittMoss

Brand new guest from the sustainable paper based grow media company PittMoss- Ashley joins the show for an episode all about sustainable growing, using paper waste for grow media, and more! Ashley talks about the prevalent use of peat moss in cannabis gardening, and goes into detail on what the peat harvesting and production process looks like. Ashley talks about the “peat bogs” where the material comes from and emphasizes that miles and miles of natural habitats are being cleared for the harvesting of this moss. She also talks about the possibility of a shortage, or a price increase in the world of peat moss, and what that might look like for the cannabis cultivation industry. Ashley also of courses discusses her alternative product PittMoss, and even made a coupon code GROWCAST for 15% off!

Purdue Northwest uses eco-friendly moss in ag-tech project

Eco-friendly PittMoss to be used in Purdue University Northwest agriculture-tech project

Ashley and Gary Borrow use eco-friendly peat moss in their local greenhouse at Purdue University Northwest.

PittMoss, made from recycled paper, is more efficient, effective, environmentally-friendly than conventional peat-based potting soils.

PITTSBURGH — Back in the 1990s, Mont Handley was managing a retail nursery and selling truckloads of Canadian peat moss when he read about how devastating its loss could be for the problem of climate change.

“A little 3% of the Earth’s land surface does way better job at sequestering or locking away carbon than the rain forests, which get a lot more publicity,” Handley said.

So he started PittMoss, a Pittsburgh-based peat substitute made from recycled paper that happens to be more effective for growing plants than traditional peat moss. He ended up on the ABC show “Shark Tank,” where he won investments from the “Sharks.”

Handley later handed off the business to an experienced investor, Brian Scott, and became Entrepreneur-in-Residence at Purdue Northwest, in Indiana. This school is doing some of the world’s most advanced agriculture-tech research, and was awarded a federal SPRINT Challenge of more than $1 million to find new solutions for the economic, health and safety risks exposed by the coronavirus pandemic.

Now, Handley is using PittMoss again in Project TRAVERSE, which also uses remotely-operated robotics to grow nutrient-rich produce. There’s a data center being built upon the site of a former coal-burning power plant on the tip of Lake Michigan, which is making a gift of a 4,000-square-foot greenhouse to Purdue Northwest. The data center’s servers are exhausting heat to serve the greenhouse.

“It’s a robotic laboratory, essentially, so we can actually start to deploy and develop ag-tech automation,” Handley said. “And so the very first thing we’re doing is going to be growing tomatoes that will be harvested remotely by workers who are sitting in their homes or offices, utilizing standard Xbox joysticks and things like that, to select and pick the right produce.”

So now Handley’s career has come full circle, and he’s using PittMoss in the greenhouse project.

“We are using PittMoss because I’m familiar with it, they asked me to be the grower, and I’m going to use the best product available to me,” he said.

They’re also working with “Plantennas” — “with a propagation pot that has a sensor embedded into it,” Handley said. “And it allows the plant to become its own unit level sensor so the robot will actually sense what the plant is and we’ll know what to do with it. We’re going to be making our Plantenna pots out of PittMoss as well.”

PittMoss, Handley said, also happens to improve aeration, nutrient absorption, and uses less water than conventional peat-based mixes.

“We feel like we can disrupt the soil economy,” said PittMoss President Brian Scott. “Instead of hauling peat moss all over the world, we can use local paper waste to grow food.”

A typical bag of soil (most are 2 cubic feet) has the same carbon emissions as burning 22 pounds of coal. Most peat moss is dug up in peat bogs in Canada and trucked south—and it’s an ecological catastrophe.

PittMoss is currently made from recycled paper and cardboard in a factory in Ambridge, Pa., near Pittsburgh.

“We’re diverting paper waste from the landfill and turning it into soils, basically,” Scott said. “We use lightly processed paper, like newsprint, coloring books, mail ads, magazines, some office paper, as well as cardboard and cardboard dust. Our vision is to have a hyper-local model in every major market to recycle local waste and distribute it locally as a soil.”’

PittMoss calculates that in 2020, its products prevented 81,111 cubic feet of peat moss from being extracted, which equates to the reduction of 811.11 metric tons of C02 emissions. That equals 893,737 pounds of coal burned, or 91,269 gallons of gasoline consumed, or 2.01 million miles driven by an average passenger vehicle.

Annually, PittMoss gives each customer an “Environmental Savings Certificate,” which displays their calculation and certifies a specific number of metric tons of C02 emissions they’ve avoided that year.

“When you fill a pot with PittMoss, it holds water better, you get way better aeration, really good biologicals — so plants absorb nutrients better — and because of that you can fertilize less and water less, and still get a bigger plant,” Scott said.

Find out more at pittmoss.com or investment opportunities at republic.co/pittmoss.

Pittsburgh based eco-friendly PittMoss expanding overseas to Lebanon

PittMoss, made from recycled paper, is more efficient, effective, environmentally-friendly than conventional peat-based potting soils

PITTSBURGH, PENNSYLVANIA—June 5, 2021: It’s a groundbreaking idea – literally.

“We feel like we can disrupt the soil economy,” says PittMoss President Brian Scott. “Instead of hauling peat moss all over the world, we can use local paper waste to grow food.”

PittMoss, the Pittsburgh-based, “Shark Tank”-invested potting soil alternative made from recycled paper, has signed a Memorandum of Understanding (MOU) to expand all the way across the world, to Lebanon. It’s a partnership with the nonprofit DTCare, to expand the world’s most environmentally-friendly potting soil to another part of the world, bringing jobs and eliminating landfill-bound paper waste.

“DTCare’s mission is to advance our goals of promoting civil society, reducing poverty (especially for women), pursuing the advancement of science and scientific research as well as providing jobs and training for veterans,” says DTCare’s president Marco Gruelle.

A new factory in Lebanon is intended to begin a virtuous cycle in a key part of the Middle East, which is teeming with refugees and struggling with poverty.

“This production facility represents a big step forward in helping to manage the flow of reusable waste materials,” says Gruelle. “We have retained experts to help make sure the soil is perfect for the climates it will encounter in the Middle East. The plant will provide a wide range of jobs. Our hope is to also make enough Pittmoss to be able to start soil remediation in the Bekaa Valley, which is the main agricultural area in Lebanon.”

“We studied Pittmoss for about a year in the Arizona desert and found that it is the perfect medium for what we are trying to accomplish, and the fact that it allows us to reuse local waste makes it perfect,” adds Gruelle.

If you’re growing food—or growing anything—PittMoss also happens to improve aeration, nutrient absorption, and uses less water than conventional peat-based mixes. It’s also a victory for the environment.

A typical bag of soil (most are 2 cubic feet) has the same carbon emissions as burning 22 pounds of coal. Most peat moss is dug up in peat bogs in Canada and trucked south—and it’s an ecological catastrophe.

“Peat bogs make up less than 3 percent of the Earth’s land mass, but sequester more carbon than all of the forests on the entire planet,” explains Scott. “They’re a massive carbon sink. You don’t even have to light it on fire–as soon as light and air hits peat moss, it will oxidize and release carbon dioxide and nitrous oxide.”

“The UN has identified elimination or reduction of peat mining as one of their top 10 carbon reduction priorities for the world.”

PittMoss is currently made from recycled paper and cardboard in a factory in Ambridge, PA, outside Pittsburgh.

“We’re diverting paper waste from the landfill and turning it into soils, basically,” says Scott. “We use lightly processed paper, like newsprint, coloring books, mail ads, magazines, some office paper, as well as cardboard and cardboard dust.”

“We are using a broader array of feedstock to prevent more and more cellulose fiber from being landfilled. Our vision is to have a hyper-local model in every major market to recycle local waste and distribute it locally as a soil.”’

PittMoss calculates that in 2020, its products prevented 81,111 cubic feet of peat moss from being extracted, which equates to the reduction of 811.11 metric tons of C02 emissions. That equals: 893,737 pounds of coal burned, or 91,269 gallons of gasoline consumed, or 2,012,680 miles driven by an average passenger vehicle.

Annually, PittMoss gives each customer an “Environmental Savings Certificate,” which displays their calculation and certifies a specific number of metric tons of C02 emissions they’ve avoided that year.

It also just works better than conventional products. Plants grow more substantial root systems and also absorb nutrients better.

“When you fill a pot with PittMoss, it holds water better, you get way better aeration, really good biologicals—so plants absorb nutrients better—and because of that you can fertilize less, and water less, and still get a bigger plant,” says Scott.

About PittMoss

PittMoss manufactures revolutionary products from organic, recycled paper. Carefully and locally sourced, our products are the result of decades-long research into the use of recycled paper fibers. The result? The best performing, most environmentally-friendly gardening mixes on the market, that also require less water! Find out more at pittmoss.com or invest today at republic.co/pittmoss.

About DTCare

DTCare’s mission is to fund and promote civil society, strive to end generational suffering, reduce and end poverty, pursue the advancement of science and scientific research, and provide jobs and job training for veterans. DTCare focuses on small to medium-sized projects which they believe will have a greater long-term effect on the people we are working with, ultimately causing positive generational change. They are headquartered in Pittsburgh and currently operate in South Africa, Panama, Bosnia and Lebanon. For more info, see dtcare.org.

Ambridge soil company PittMoss looking to help gardeners, go global while staying local

5/14/21

The company saw a 127% increase in sales at the beginning of 2021 and expects that trend to continue.

PTL Earth Week: Pitt Moss Alternative

4/20/21

Pittsburgh Today Live’s Mikey Hood visits Ambridge where they are making an environmentally-friendly alternative to peat moss. It’s called Pitt Moss and it’s great for your garden.

PittMoss announces new equity crowd-funding campaign through Republic

PittMoss, made from recycled paper, is more efficient, effective, environmentally-friendly than conventional peat-based potting soils

PITTSBURGH, PENNSYLVANIA—March 8, 2021: PittMoss, the “Shark Tank”-invested maker of the world’s most environmentally-friendly potting soil, is announcing a new equity crowd-investing campaign through Republic (republic.co/pittmoss), where the public can own part of the company.

This $300,000 campaign will enable smaller investors to become a part of this startup success story, which is disrupting the old and dirty market of peat-based potting soils. Their previous campaign through Republic, which closed on Aug. 16, raised $237,107, which was 948% of their goal. It can be found at http://rep.pub/invest-pittmoss.

Until the Republic campaigns, PittMoss was only able to accept money from accredited high-net-worth investors.

“A lot of our fans have seen us on Shark Tank,’ and they’re like, ‘Man, I’d love to invest along with Mark Cuban and the sharks,’ says PittMoss president Brian Scott. “So now this is an opportunity to allow them to do it, and I know we’re going to have a lot of customers excited about doing it.”

PittMoss is made from recycled paper in a factory in Ambridge, PA, outside Pittsburgh (hence the name PittMoss). Last year, the company grew at a 41% rate. PittMoss is unique in that it’s a triple-bottom-line company.

“It’s got a positive social impact, environmental impact, and financial impact. You’re investing in a company that does good,” says Scott.

The carbon emissions from a typical bag of soil (most are 2 cubic feet) are similar to burning 22 lbs. of coal. Most peat moss is dug up in peat bogs in Canada and trucked south—and it’s an ecological catastrophe.

“I believe in doing as little harm to the planet as possible,” says Value-Add investor Paul Straub. “I had no idea how harmful peat mining was. and I really like that PittMoss is working to reduce the amount of fibrous waste.”

“Peat bogs sequester more carbon than all of the forests on the entire planet,” explains Scott. “They’re a massive carbon sink. The UN has identified elimination or reduction of peat mining as one of their top 10 carbon reduction priorities for the world.”

“We’re diverting paper waste from the landfill and turning it into soils, basically,” says Scott. “We use lightly processed paper, like newsprint, coloring books, mail ads, magazines, some office paper, as well as cardboard and cardboard dust. If you looked at our factory, every day we get USA Today, New York Times, the Wall Street Journal.”

“We are using a broader array of feedstock to prevent more and more cellulose fiber from being landfilled. Our vision is to have a hyper-local model in every major market to recycle local waste and distribute it locally as a soil.”

PittMoss calculates that in 2020, its products prevented 81,111 cubic feet of peat moss from being extracted, which equates to the reduction of 811.11 metric tons of C02 emissions. That equals: 893,737 pounds of coal burned, or 91,269 gallons of gasoline consumed, or 2,012,680 miles driven by an average passenger vehicle.

Annually, PittMoss gives each customer an Environmental Savings Certificate,” which displays their calculation and certifies a specific number of metric tons of C02 emissions they’ve avoided that year.

It also just works better than conventional products. Plants grow more substantial root systems and also absorb nutrients better.

“PittMoss is an important improvement over our previously-used products” says Value-Add Investor Joyce A. Mitchell. PittMoss yields better results and is Earth-friendly. Repurposing waste will give Mother Nature a helping hand.”

Although they had more than 1,000 investors in the last campaign, many people who wanted to invest in PittMoss were still left out. And others who had previously invested wanted to do it again. So, they decided a new campaign was in order. It begins today, March 8, 2021

“In this crowdfunding round, all investment levels receive free PittMoss product and equity in the

business, so it’s a great opportunity for passionate gardeners and loyal followers to support a

local company growing bigger and healthier plants and improving the planet” said Scott.

There’s also a gift for every investor in the Republic campaign.

Interested investors should visit http://rep.pub/invest-pittmoss to learn more.

About PittMoss

PittMoss® manufactures revolutionary products from organic, recycled paper. Carefully and locally sourced, our products are the result of decades-long research into the use of recycled paper fibers. The result? The best performing, most environmentally-friendly gardening mixes on the market that also require less water! Find out more at pittmoss.com

About Republic

Founded in 2016, Republic operates under U.S. equity crowdfunding regulations and is under the supervision of the U.S. Securities and Exchange Commission and the U.S. Financial Industry Regulatory Authority. For additional information, please visit www.republic.co, @joinrepublic, and www.facebook.com/joinrepublic

PittMoss Helping Area Residents Grow Fresh Produce at Home

4/20/20

PittMoss based in Ambridge, is giving away free produce seeds to its customers with every purchase of its Plentiful Organic Potting Mix and discounting products to help customers start their own gardens at a time when many are concerned about the food available to their families.

PittMoss will deliver its recycled soil with seed packets so you can start a Victory Garden

4/13/20

The Ambridge-based company, a 2014 winner of “Shark Tank” — for its environmentally-friendly alternative to peat-based potting soil — is offering packets of seeds for carrots, tomatoes and lettuce with every purchase of its Plentiful Organic Potting Mix, made for gardens or raised beds

Grow From Home: Local Company Offering Way For Pittsburghers To Grow Produce At Home

4/11/20

PittMoss is a local company that uses recycled materials for potting mix. They say it can be used for planting veggies in your backyard or a hanging basket without the messiness of dirt.

Here Are Six Sustainable Products for Starting Your Spring Seeds

4/25/17

PittMoss, a product made from recycled paper, is another peat moss-free option. Featured on the ABC TV show Shark Tank in April 2015, this is its first year on the market for non-commercial growers.

PittMoss: The magic is in the mix for this planting medium

4/14/17

In the past, PittMoss has only provided its product to commercial growers, but this season PittMoss is available locally at garden centers, through Amazon and the company’s website. It’s super absorbent, and doesn’t need to be watered as often as other mediums, because it drains well, Scott says.

PittMoss brings their sustainable, “Shark Tank”-approved planting mixes to home gardeners

2/15/17

Modeled off the fluffy, moisture-retentive qualities of peat, PittMoss is touted as delivering more life-giving materials to plants.

PittMoss Introduces Their Revolutionary Growing Media to the Public

2/15/17

PittMoss, who previously sold its growing media only to commercial growers, announces its products are available for retail sale. PittMoss manufactures next-generation gardening amendments and mixes, unlike anything available on the market. Their products have been rigorously tested in EPA and greenhouse trials, consistently outperforming the competition.