Get Started with Plentiful

Read Reviews

- Our Products

- Store Locator

- About Us

Why Use Pittmoss

- Contact Us

Technical Data

PittMoss is comprised of formatted ligno-cellulosic fibers. The fibers are formatted into particles through a patented process that granulates the fibers to maximize internal pore spaces within an individual particle.The particles are slightly ridged, spherical to semi-spherical, and occasionally flattened or elongated.The material is hydrophilic. The total aggregate serves to hold and absorb air, water, and other fluids. It has primary applications in agriculture, horticulture, and where a naturally carbon rich substrate is desirable

Raw Materials

PittMoss is made of cellulose, hemicellulose, lignin, and proprietary natural additives.It is primarily derived from recycled newspaper and/or other cellulose based materials.

Physical Properties

| Dry Bulk Density: | As shipped: 0.25-0.4g/cc |

| Oven dry: | 0.1-0.14g/cc |

| Typical Moisture: | 50 to 70% of total massat manufacture |

| Moisture Holding Capacity: | 60 to 70% by volume as shipped or 5 to 6 times dry weight |

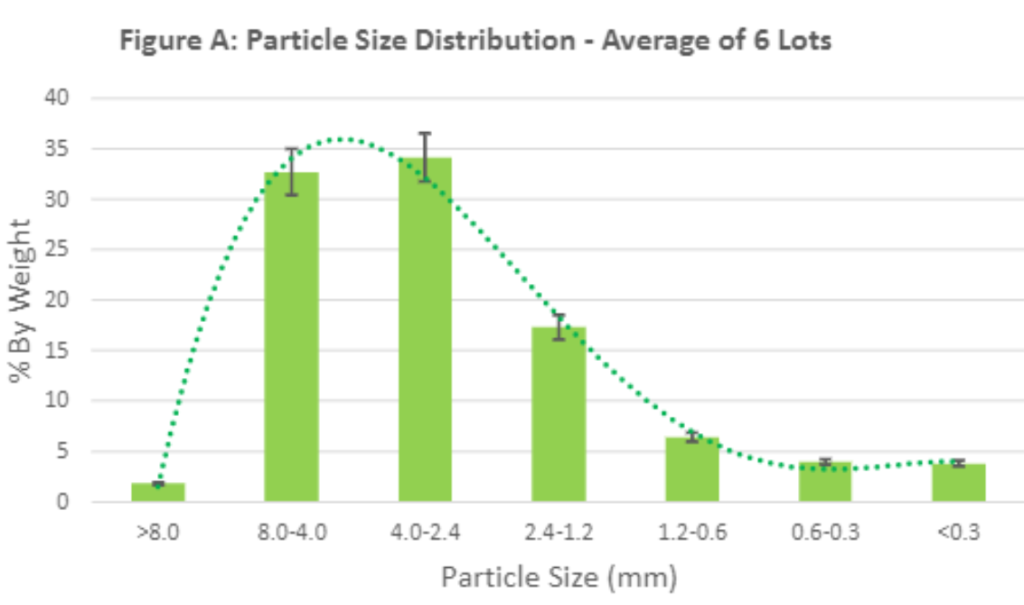

| Particle Size Distribution: | See Figure A |

| Air Porosityat Saturation: | 8 to 20 % (depending on compaction) |

Chemical Properties

| pH: | 6.5 –7.5 |

| EC: | 0.2 –0.4 (SME) |

| CEC: | 10-15meq/100 grams |

| C/N Ratio: | 200 –300:1 |

| Typical SME Analysis: | See Table 1 |

| Contaminants: | None |

Biological Properties

| Base Materials: | Cellulose, hemicellulose, lignin, and proprietary additives |

| Flora and Fauna: | Pathogen free, no insects, or plant disease organisms at manufacturing |

Environmental Compatibility

| Air: | No known volatile or noxious compounds |

| Water: | Fully compatible, non-polluting, no toxic leachates |

| Soil: | Combines with the soil like other cellulosic materials (leaves, grass, wood, etc.) |

| Fish & Wildlife: | No known toxic materials. |

Table 1: Typical Mineral Content In a Water Saturated Media Extract Analysis

| Mineral | PPM |

| Nitrate | 0 - 2.0 |

| Ammonium | 0 - 1.0 |

| Phosphorus | 1.0 - 4.0 |

| Potassium | 1.0 - 4.0 |

| Calcium | 30 - 60 |

| Magnesium | 2.0 - 8.0 |

| Sulfur | 50 - 90 |

| Boron | 0 - 0.3 |

| Iron | 0 - 2.0 |

| Manganese | 0 - 2.0 |

| Copper | 0.3 - 1.0 |

| Zinc | 0 - 0.1 |

| Molybdenum | 0 - 0.05 |

| Aluminum | 0.2 - 2.0 |

| Sodium | 20 - 40 |

| Chloride | 10 - 25 |