- Our Products

- Store Locator

- About Us

Why Use Pittmoss

- Contact Us

Water Efficiency

A Review of Some Key Findings

Following the invention of the PittMoss® engineered fibers it became apparent that the goal of improving the internal and external porosity of the particles provided the desired structure for both increased water availability along with increased air porosity. This was because the substrate had less space occupied by solids and the correct balance of macro- and micropores. One of the end results was greatly improved water efficiency when growing in blends containing PittMoss®. Discussed in this paper are summaries of some key observations over the past 8 years that demonstrate how PittMoss® works to increase the rate and volume of water absorption, retention, and availability in the substrate alone and in growing blends.

Air and Water Relations in Substrates

To understand the influences PittMoss® engineered growing substrates have on water dynamics, it is first necessary to understand how water and air interact and how the properties of a given growing substrate influence water management in container growing. It is important to recognize that most water held within a growing blend is available to plants, while a smaller portion of water is held so tightly that plants cannot pull the water out of the substrate.

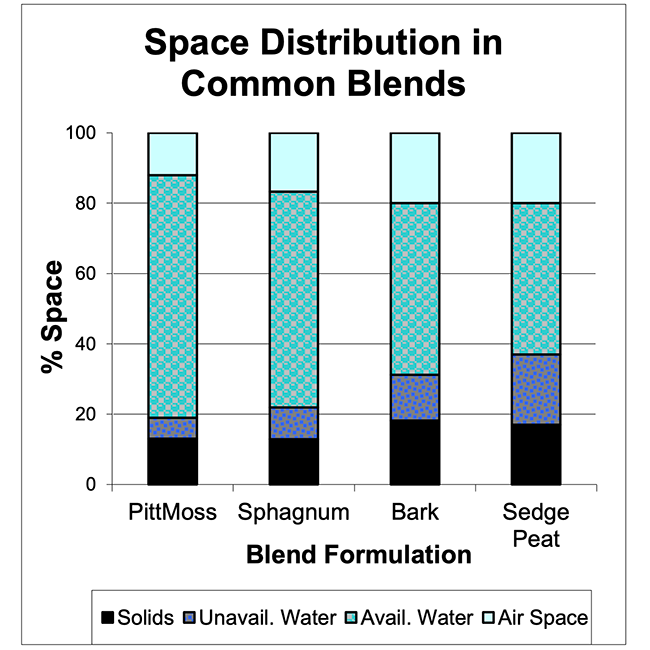

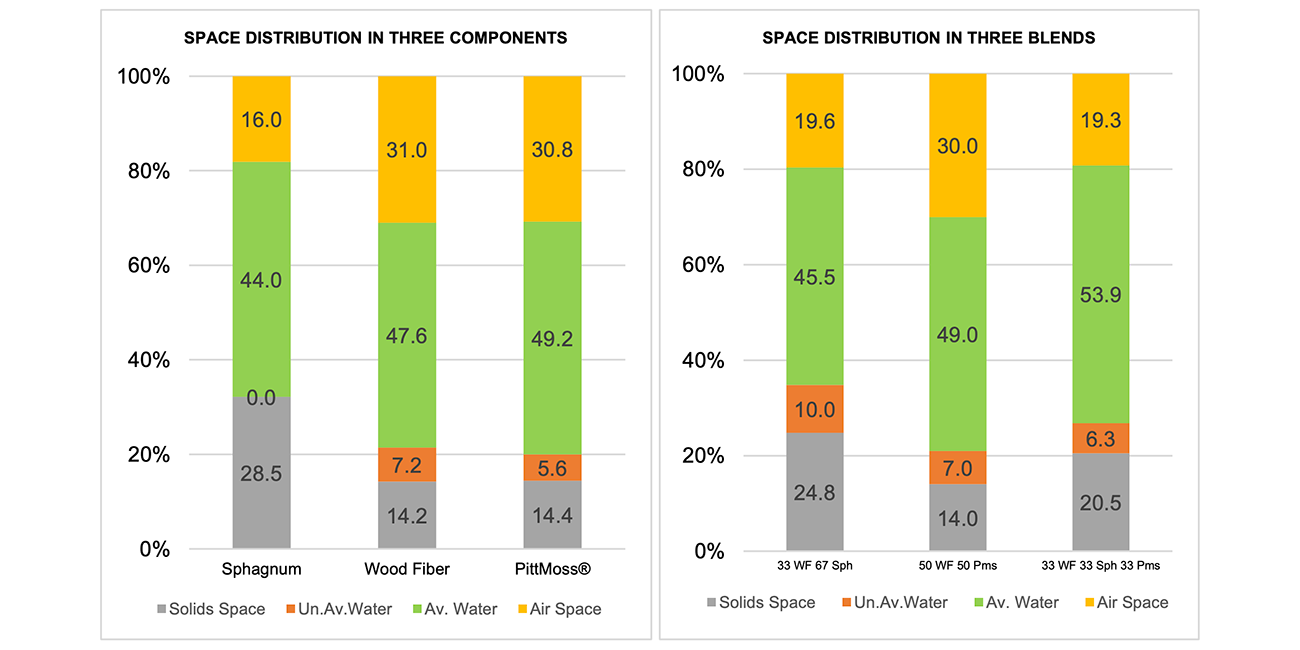

The best way to understand the quantity of water available in a substrate is to understand the basic air/water relations. Efficiency can be demonstrated by examining the spaces that are filled with air and available water after watering to full saturation and draining. Figure 1 presents examples of space utilization of four different substrate components. The bottoms of the columns depict the space occupied by particles providing no available space for water or air. Above the solids in each column is presented a depiction of the unavailable water. Unavailable water is the water held so tightly by the substrate that at the permanent wilting point the plant cannot pull the water out. Note that PittMoss® has a low level of unavailable water. Graphically represented above the unavailable water is the plant available water. That is the water in freshly saturated growing mix that is readily available for use by plants. Given the greater volume of plant available water in PittMoss® as compared to other substrates, it is this property that likely gives blends containing PittMoss® the ability to supply plants with water longer before requiring watering or causing wilting. At the top of the columns is the air space that exists when the substrate is fully saturated and drained. Too much air space decreases plant available water, and too little air space inhibits gas exchange. Optimal air space is usually considered to range from 5 to 15%. Studies as early as 2014 showed that PittMoss® provides a very high pore space per unit volume and delivers more plant available water while retaining sufficient gas exchange properties in container growing.

Figure 1. An example of space distribution in common substrates illustrating (from bottom to top) volume occupied by solid materials unavailable water, plant available water and air.

Rate of Water Absorption By PittMoss® Compared To Sphagnum Peat

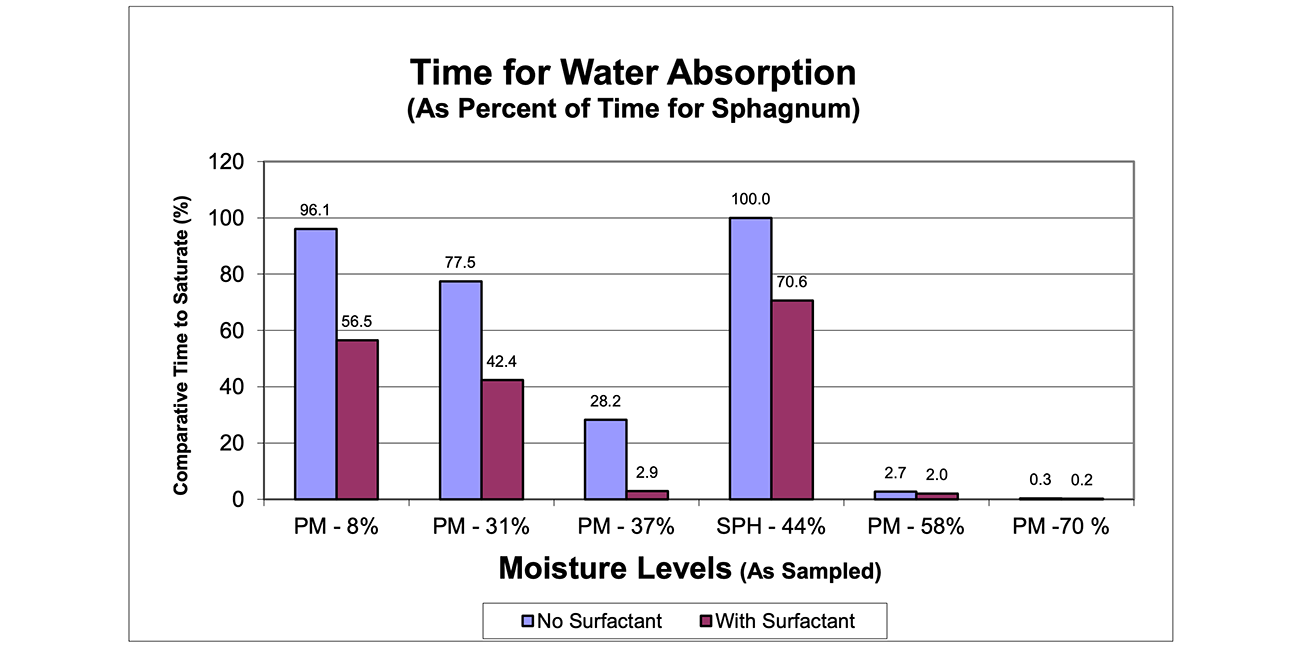

Soon after its invention it was observed that PittMoss® absorbs water much more readily than dry sphagnum peat. The hydrophilic, or “water loving,” nature of the engineered fibers of PittMoss® saturate much more readily than peat. It was noted that this was the case both with and without the use of surfactants (wetting agents). A brief study was conducted in 2015 examining water absorption rates of PittMoss® at various moisture levels compared to common sphagnum peat. Samples of PittMoss® that contained from 8% to 70% moisture by weight were prepared. A sample of sphagnum was drawn from a commercial compressed bale that contained 44% moisture. Triplicate samples for each treatment were uniformly packed into clear plastic cups that held 283ml of substrate. Each cup had three holes in the bottom. The cups were suspended in a bath of pure tap water and another bath of tap water plus 600ppm of the surfactant AquaGro–L. The time was measured for full absorption of water through the holes in the bottom of the cup up to the top of the substrate. Comparisons of the times were made using the sphagnum in the clear water treatment as a reference as 100%. The average data for all 12 treatment levels is presented in Figure 2. Additionally, the data for PittMoss® when extrapolated to a 44% moisture level (to equally compare the materials at the same moisture level) showed that all PittMoss® samples, even down to 8% moisture, absorbed water more readily than the sphagnum peat at 44% moisture. This data is presented in Figure 3.

Figure 2. A comparison of wetting time between sphagnum peat and PittMoss® at various moisture levels with and without surfactant (wetting agent).

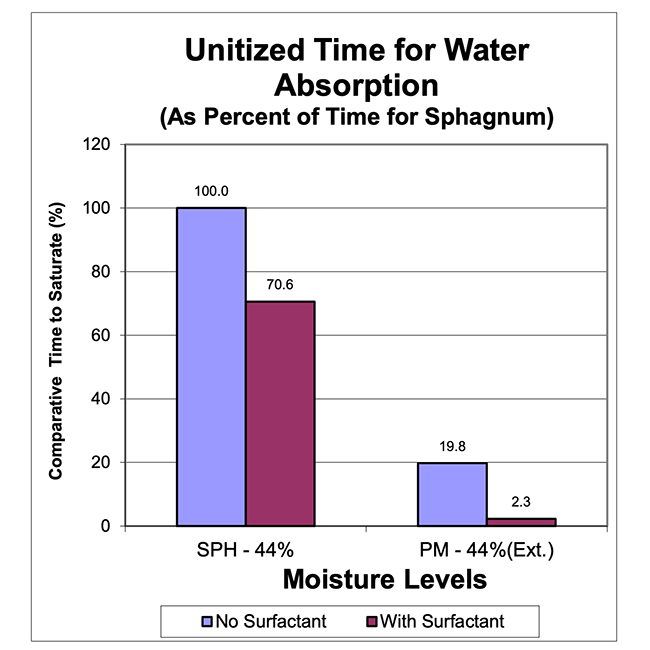

The data also demonstrated that the surfactant accelerated the absorption in both materials at all moisture levels. When adjustments are made to compare both materials at 44% moisture, it is possible to directly

compare the two substrates. Figure 3 shows that without a surfactant present PittMoss® fully absorbed the water in only 19.8% of the time that it took for sphagnum peat to do the same. That is about 5 times faster. With a surfactant, the sphagnum absorption time was cut to 70.6% of the initial of the initial rate, while the PittMoss® time to full absorption was reduced to only 2.3% of that of the untreated sphagnum.

This data shows that:

- PittMoss is much more hydrophilic even at lower moisture levels than sphagnum.

- Sphagnum is quite hydrophobic when dry.

- Surfactants accelerate water absorption in both materials.

While this was a simple evaluation, it strongly suggests that PittMoss®, whether alone or in a blend, will serve to absorb water much more readily and be of great help in increasing water use efficiency and

management when growing plants.

Figure 3. A comparison of wetting time between sphagnum peat and PittMoss® with and without surfactant. The PittMoss® rate is extrapolated to 44% moisture for a comparison to sphagnum as received at 44%.

Total Water Holding Capacity

Total water holding capacity is the amount of water held within a substrate after it has been saturated and drained by gravity. The measurement includes both plant available and unavailable water. The quantity of water held within a substrate is dependent on the size and amount of pore spaces. The “Total Water Holding Capacity” (TWHC or %WHC) is sometimes referred to as the “Capacity of Water Retention” (CRW, or %CRW). The values are expressed as a percentage of the weight (not volume) of the substrate dry matter (e.g., a WHC of 650% means 1g of oven dry substrate holds up to 6.5g water after the excess gravitational water has drained). PittMoss® has an exceptional quantity and array of internal pore spaces, making the total porosity, and specifically the water holding capacity, very high (631% WHC). Table 1 provides a comparison of PittMoss® to an array of peat types, substrate components, and some blends that are reported in scientific literature. Gelatinous materials produced by microbes in the substrate can work like glues that can dry and permanently fill pores. Often, these materials will solidify when drying and cannot rehydrate when remoistened. Therefore, sample handling and processing systems should avoid excessive drying (except for measuring dry bulk density) of the substrates before physical analyses because that can greatly alter the nature of the components and will not represent the conditions in production.

| Substrate/Blend | %WHC (Dry Material Basis)* | * References/Sources |

| PittMoss – Regular | 631 | C.L .Bethke 11/9/14 |

| PittMoss – Fine | 520 | C.L. Bethke 11/9/14 |

| Sphagnum – Annapolis Valley | 620 | Abad, M. et al. 2005 |

| Sphagnum (H2-H4) | 614 | Sambo, P. et al. 2008 |

| Sphagnum | 50 | Mastalerz, J. 1977 |

| Peat-Sedge | 200-361 | Mastalerz, J. 1977 |

| Coir – IC1 | 276 | Abad, M. et al. 2005 |

| Peat Amorphous - Ireland | 450 | Huat, et al., 2011 |

| Fibric Peat | -640 | Boelter D. H. 1968 |

| Sapric Peat | -340 | Boelter D. H. 1968 |

| Hemic Peat | -220 | Boelter D. H. 1968 |

| Composted Dairy Manure | 182 | Mastalerz, J. 1977 |

| Sph.(50%)/ Clay Loam (50%) | 115 | Mastalerz, J. 1977 |

Tabel 1. A survey of data reported on total water holding capacity (%WHC) when saturated and drained.

*Expressed as a percent of dry matter (e.g.,650% means 1 gram of dry matter holds 6.5 grams of water when saturated and the excess is drained).

Some Examples of PittMoss® Incorporated Into Growing Blends

Replacing Sphagnum Peat with PittMoss® In a Bark Blend

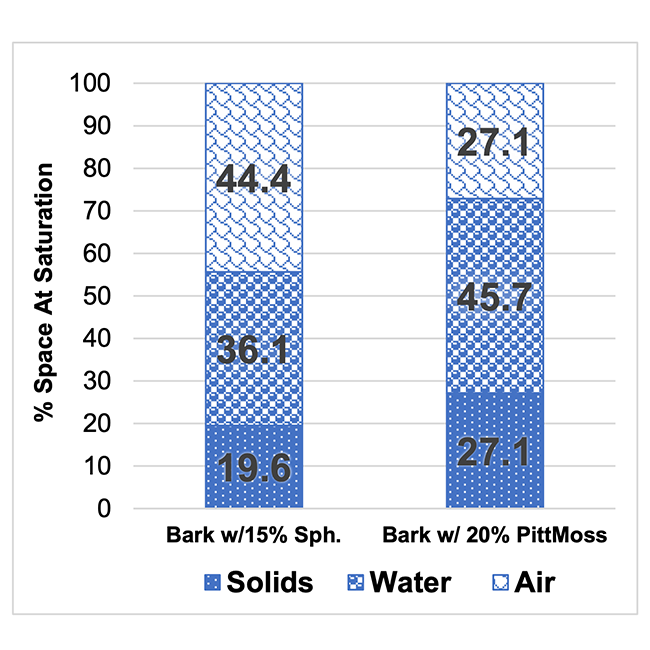

In this comparison, a nursery blend which incorporated 15% sphagnum peat with pine bark was the grower’s typical mix. The sphagnum was replaced with 20% PittMoss®. As a result, the water holding capacity of the nursery blend increased from 36.1% to 45.7%, representing a 26.8% increase in the total water held within the growing medium. Additionally, in this comparison, the solids within the blend increased from 19.6% to 27.1% with the added PittMoss®. These results are shown in Figure 4. The increased WHC and solids content are likely due to PittMoss® filling in excessive amounts of large air spaces and some providing more micropores that hold water thus increasing water holding capacity. While this was a single observation from a single grower with a blend provided by a specific mixing company, it does provide very significant indications that using PittMoss® to replace sphagnum peat in the bark-based mixes could have a very significant impact on the water holding capacity in these mixes and also provide a more economical and environmentally sustainable way of improving the water efficiency while reducing run-off when using bark-based blends.

Figure 4. Comparison of air, water, & solids after saturation and drainage of two bark blends replacing sphagnum with PittMoss®.

Observations on Wood Fiber and PittMoss Blends

Preliminary trials were performed in 2019 in the pursuit of producing more sustainable growing substrates for horticultural use. One aspect of the project was evaluating the effects of PittMoss® in combination with wood fiber on aeration and water availability.

In these tests, three components (PittMoss®, wood fiber, and sphagnum peat), were compared alone and combined as blends of the following: 50% PittMoss® with 50% wood fiber, 67% sphagnum with 33% wood fiber, and 33% PittMoss®, 33% wood fiber with 33% sphagnum. The PittMoss® was the “Grower Grade-F” formulation, while the sphagnum was Lambert standard retail grade, and the wood fiber was standard grade obtained from a grower. All sample blends were hand mixed at moderate but low moisture content and run through a ¼ inch screen to ensure uniform mixing and no clumping. The air space and water holding capacity were measured using cup in cup methods where the samples were saturated, left at saturation for 24 hours, then allowed to drain. The drainage was then collected. Using the collected data and making an estimate of unavailable water (water held at tensions greater than roots can pull it from the blend), space distributions were calculated. The same methods were applied to all components and blends. Figure 5 shows the results of this experiment. In the straight media components, the available water was greatest in PittMoss®. A curious effect was that when combining equal portions of PittMoss®, sphagnum and wood fiber, the greatest porosity was created and available water was the highest (53.9% of space) of all blends tested. Note that these measurements were not replicated and should not be considered definitive but should rather be treated as observations only.

Figure 5. A comparison of space distribution of solids, unavailable water, plant available water, and air between individual components as well as blends of sphagnum peat, wood fiber, and PittMoss® following drainage after saturation.

Moisture Content While Growing in Large Containers

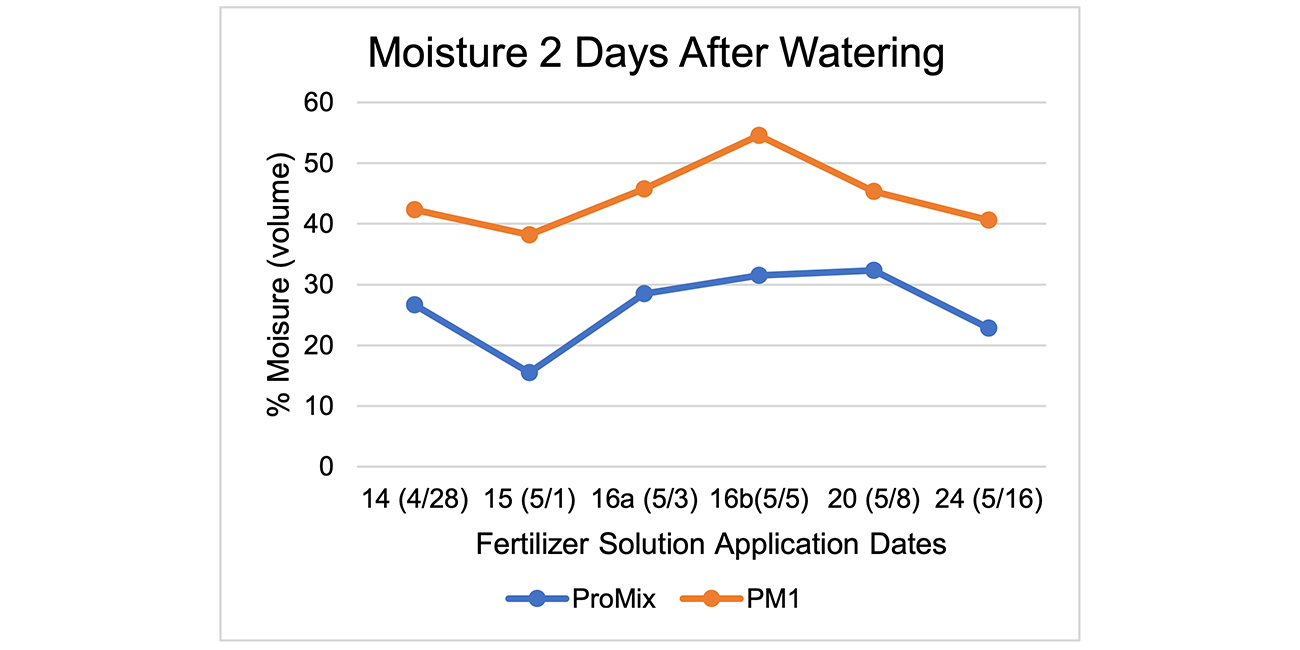

A grower in Northern PA worked in cooperation with PittMoss LLC to monitor moisture after water applications using a Blue Lab “Pulse Meter.” This grower was growing crops in large pots that held 7 gallons of substrate. The “Pulse Meter” reports the volume of water in the substrate using radio waves. The moisture level was recorded two days after application of nutrient solutions comparing ProMix (a peat perlite blend) and PittMoss® PM1 (a peat-reduced blend containing 30% PittMoss®). The results are illustrated in Figure 6. After drainage, the retained moisture in the PM1 blend was consistently higher, averaging 69% higher, than in the ProMix. The plants had more available water reserves and likely benefited from the increased supply of plant available water containing the applied nutrients. The additional water holding capacity also allows for increased time intervals between nutrient solution applications and reduced the possibility of moisture stress between applications. As a result, the crop performed better. According to the grower, yields were lower in the ProMix blend (by possibly 10 to 15%).

Figure 6. Moisture comparison at various fertilizer application dates two days after watering.

Summary of Water Efficiencies Observed to Date

The above selected observations provide support for the current studies underway which compare water applied in growing crops in various substrates with and without PittMoss ®. These studies are recording the effects of applied water on the resulting growth of plants while also comparing the amount and frequency of applications, quantity of run-off, and ultimate extensions in time to wilting in finished crops in different substrates.

Some key observations to date on the water use efficiency of PittMoss® are:

- PittMoss® increases the plant-available water in containers of assorted sizes.

- PittMoss® improves absorption due to more hydrophilic properties.

- PittMoss® increases retention of applied water.

- PittMoss® allows for greater release of water than other common substrate components.

- Blends containing various portions of PittMoss® have increased water availability.