- Our Products

- Store Locator

- About Us

Why Use Pittmoss

- Contact Us

Comparing the Physical Properties of Varying Blends of Sphagnum Peat, PittMoss and Perlite

Most sources of sphagnum peat moss have a proper physical structure to supply sufficient aeration and high water holding capacity for potting soils and container blends. However, recent challenges to the availability of sphagnum have developed. Supplies in Europe are more limited. Environmental concerns influence sphagnum peat supplies in many areas. Weather conditions limit harvest in North America. These challenges lead to the examination of alternative growing mix components that can serve as a substitute for sphagnum. One such material that has been developed is PittMoss,® an engineered cellulosic fiber designed to provide plant roots with optimal water, air exchange, and nutrients. Mont Handley developed PittMoss® in Pittsburgh, PA using recycled organic materials. Due to its resemblance of coarse sphagnum peat, he named it “PittMoss®”. It is lightweight, mixable, water absorbent (hydrophilic), slightly acidic (pH 5.7 to 6.7), low in soluble salts, and easy to incorporate into growing media blends. These manufactured fibers are derived from recycled organic materials that are sustainable and earth-friendly― a hot-button topic in the current garden industry.

This study was conducted to compare the physical characteristics of PittMoss® to sphagnum peat when blended. Because PittMoss® shares qualities of sphagnum peat moss, this study focuses on physical characteristics most important to the greenhouse and container plant industry.

The Study

Sphagnum peat and PittMoss® were evaluated for air and water properties. A Manitoba coarse sphagnum was used for the comparison with PittMoss®. Three arrays (1. Sphagnum & Perlite, 2.PittMoss & Perlite, and 3. PittMoss® & Sphagnum) of ten blends (2 controls + 8 blends) each were formulated with increasing increments (12.5%) of perlite, sphagnum, or PittMoss®. The controls were also mixed the same as the eight blends. These 30 treatments were compared. After blending, samples in triplicate were drawn from each of the treatments and controls. They were used to fill the plastic cups (283 ml, 11.2 cm tall) with holes drilled in the bottom. Each filled cup was lightly packed, re-heaped full, then lightly tamped down three times with a weighted canister (equivalent to 50 lbs/cu ft.) and leveled to the top of the cup. The filled cups with drainage holes were inserted into identical cups with no holes. The filled cups were then fully saturated with water and left to equilibrate for 24 hours. They were then refilled with water to the top. Each cup was then lifted and held over the lower cup with spacers to drain for 24 hours when data was taken for each of the 90 samples.

Data Collection and Analysis

A base tare weight of the cup and the residual water held in the lower cup was determined. That was the tare weight before drainage. The drained water and the moist cups of substrate were weighed and then adjusted for that tare weight. The drained water provided a measure of the air filled pore space at saturation. Dry bulk densities of the individual components were measured on samples dried in an oven at 220°F for 24 hours. The dry bulk densities were then used to calculate the weight of dry materials in each cup. Then, by difference, the volume of only the total water retained at saturation was determined for each cup. The total water retained included both plant available and unavailable water. A measure of unavailable water was assumed to be approximately equal to the water retained in the substrate when it was air dry. This approximation of unavailable water was determined by measuring the moisture that remained in the individual components when air dry, (i.e. unavailable water escapes between air dry and oven dry) and then using those values to calculate the amount of unavailable water expected to remain in a cup when air dry. By subtracting the estimated unavailable water from the total water retained, we get the plant available water. These parameters of air porosity, plant available water, unavailable water, and solids help to then define the physical properties of each component. Graphs and tables that represent the properties are presented here.

Results

Bulk densities

The highest performance in the “Roma” tomatoes was in the PM1 blend. It exceeded all others in height and branching, achieving a score of 108.2% of the mean comparison. Both the House blend and the BM6 had the lowest performance at 91.9% and 94.6% respectively. The addition of 30% Grower Grade PittMoss® to BM6, making BM6GG, produced a significant increase in the performance, to score 104.0% of the mean, compared to 94.6% without the PittMoss. That increase was reflected in the higher fresh weight and taller plants. The number of axillary shoots was about the same for the BM6, PM1, and BM6GG. The representative photos show the differences that can be seen at 48 days of growth. Branching was greater in the BM6GG, with the added PittMoss®. The growth was about the same for the first three weeks in all blends, after which the blends with the PittMoss® advanced. This suggests that the primary benefits of the PittMoss® relate to increased available water and nutrient reserves.

TABLE 1: BULK DENSITIES OF THE COMPONENTS

| Component | As Received | Oven Dry | ||

| Grams Per Cubic Centimeter | Pounds Per Cubic Foot | Grams Per Cubic Centimeter | Pounds Per Cubic Foot | |

| PittMoss® | 0.31 | 19.3 | 0.119 | 7.4 |

| Sphagnum(M) | 0.13 | 8.1 | 0.092 | 5.7 |

| Perlite(Crs.) | 0.12 | 7.5 | 0.097 | 6.1 |

Particle Sizes

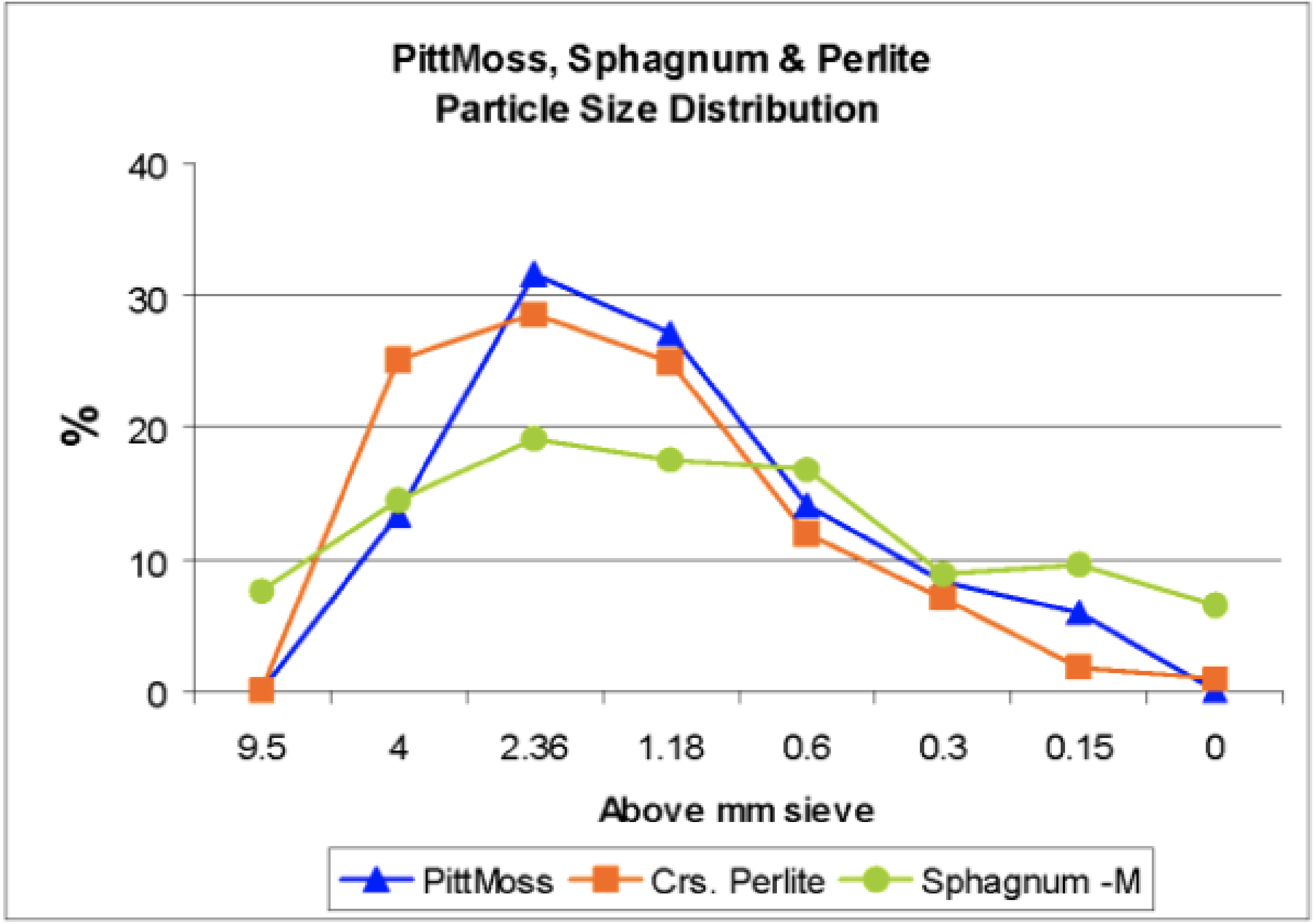

Particle size distributions are presented in Figures 1. This figure shows the percentages by weight of each component that passed through the larger sieve and remained held above the next finer sieve without passing through it. It provides the “fingerprints” of the distribution of particle sizes for each component.

FIGURE 1: PARTICLE SIZE DISTRIBUTION

In comparing these “fingerprints, ” the particle sizes of the PittMoss® are larger than those of the coarse sphagnum, resembling those of the perlite. This is thought to result from the formation of pedules, or “peds, ” which are little bundles or balls of the engineered fibers of PittMoss®. It should be noted that the “peds” are more pliable, compressing and re-forming more easily than sphagnum, and much more easily than perlite. The potential influences from the pliability of these PittMoss® “peds” can only be realized in blending and making measurements of those blends. When blending components together, the particles, regardless of source, bump and bridge together to create the large pore spaces. The coarser and medium sized particles combine to provide air space and drainage. The finer materials, which are those below 1.0 mm, tend to fill in pore spaces and decrease air porosity. PittMoss® has a very low percentage of fine particles; however, it is more flexible than either perlite or sphagnum, and its shape will be altered in a blend. Additionally, when PittMoss® is very dry, it becomes more brittle and can be broken down into fine particles, and if processed or blended when dry, the amount of fine particles will increase. While the particle sizes provide an estimate of how the materials may intermingle, the particle sizes do not identify the water absorptive properties or give any suggestion as to how shapes and surfaces of the blended materials will work together. As one can see, PittMoss® demonstrates favorable particle size distribution compared to this coarse sphagnum sample.

Space Distribution in Blends

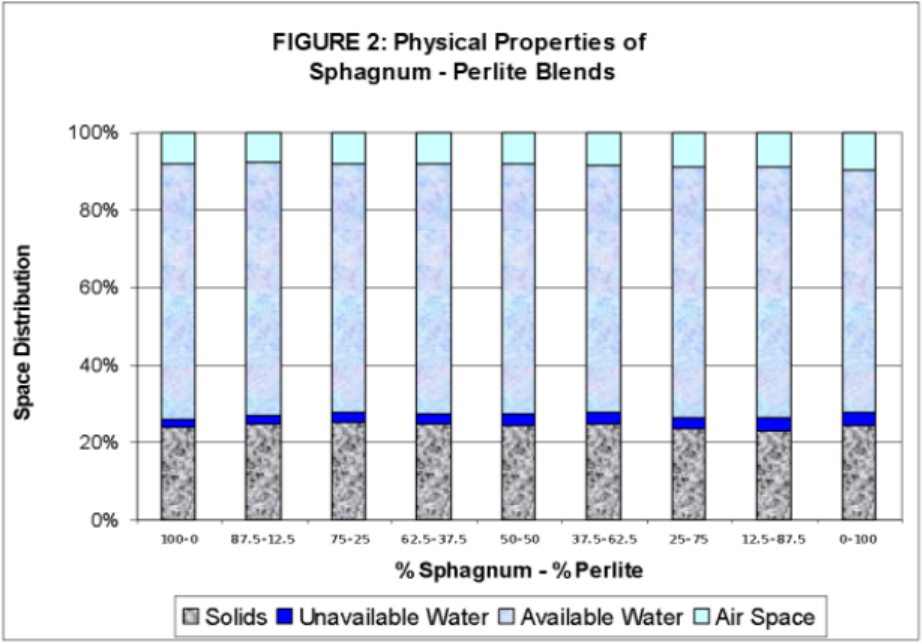

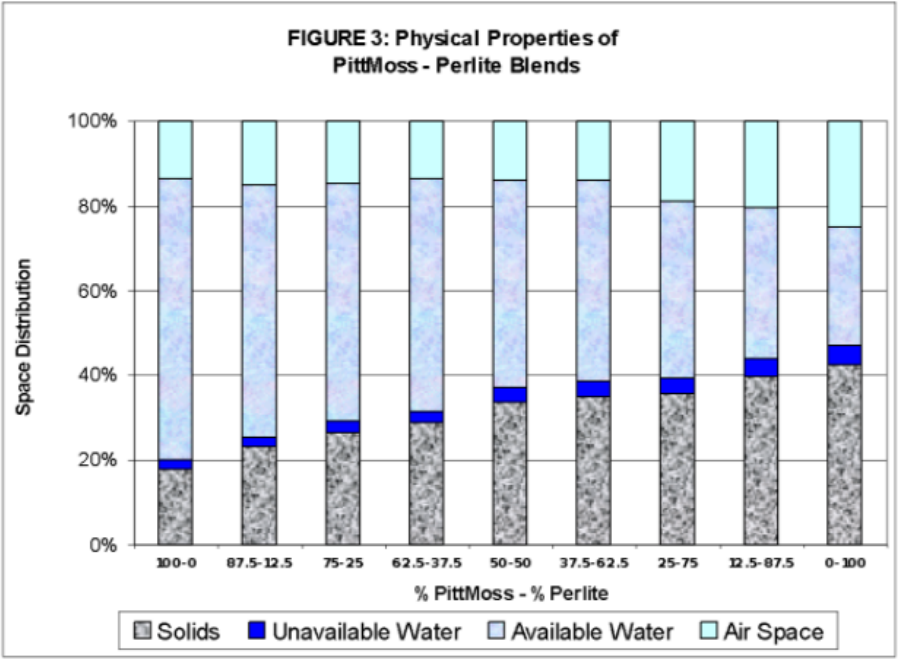

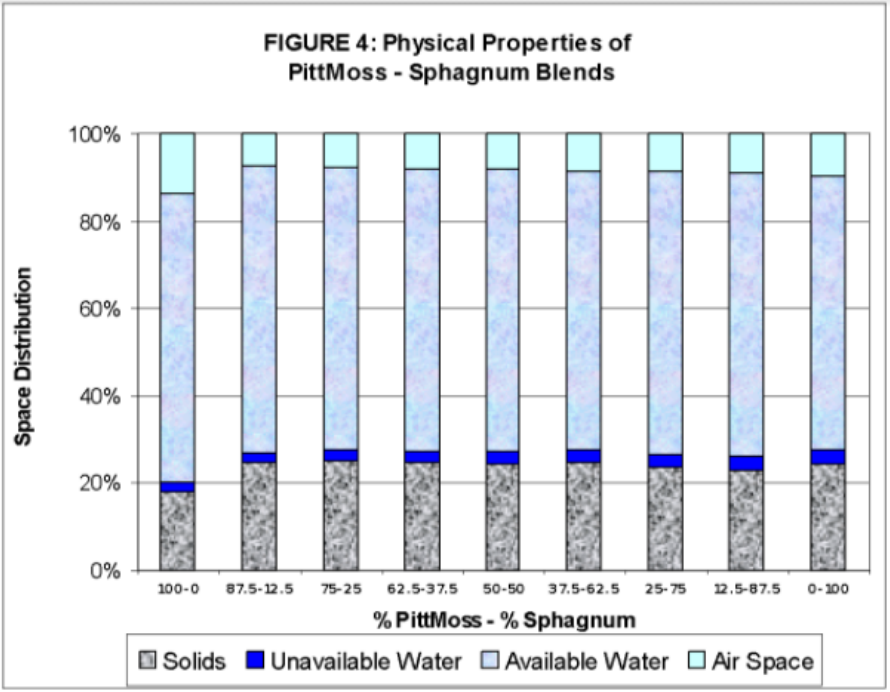

IIn making growing media blends, the components intermingle to influence the air-water relationships. The composites in Figures 2 through 4 show how coarse sphagnum and PittMoss® when combined with perlite, and with each other, influence space utilization. The data are presented on a percent volume basis in each figure. The breakouts for each property are presented in Figures 5-8. Note that all of these representations show the properties present in a settled or compacted (50 lbs./sq ft.) and saturated substrate about 4.4” (11.2 cm) deep. In containers of different depths and in loose-filled containers, the numbers will be considerably different.

Figure 2 shows sphagnum combined with perlite. Figure 3 depicts PittMoss® blended with perlite. Figure 4 shows coarse sphagnum and PittMoss® blended together. Each blend shows the space distribution as solids, unavailable water, available water, and air space at saturation. Figures 2 and 3 are remarkably similar, suggesting a general similarity of how coarse sphagnum and PittMoss® blend with perlite.

Figure 4 shows what happens when PittMoss® is incrementally replaced with coarse sphagnum. The changes due to different ratios are mostly insignificant, indicating that PittMoss® can effectively replace coarse sphagnum. Further breakouts of the physical characteristics are presented in Figures 5 through 9. They show the similarities and differences between PittMoss® and sphagnum.

Solids

Figure 5 presents the variation in the percentages of solids as the ratios change with each of the blending pairs. In the sphagnum-perlite blends, the percentages of solids increases nearly linearly with increasing perlite, ranging from a low of 24% in pure sphagnum to a high of about 42% in pure perlite. A slight downward bending in the middle implies a slight decrease in solids at the middle ratios, indicating some bridging of the coarse sphagnum with the perlite. The PittMoss® curve starts at a lower level of solids for pure PittMoss®, 18%, and has a nearly linear slope up to pure perlite at 42%. Conversely, it has a slight upward curve in the middle. That is an indication that the PittMoss® may be intermingling at a low level to increase the consumption of space by solid materials, which may be due to the pliability of the PittMoss®. The solids in the blends of PittMoss® and sphagnum appear to yield a straight line with a slight incline from the 18% solids in pure PittMoss® up to the 24% in coarse sphagnum. An interesting observation is the sudden jump in solids when only 12.5% coarse sphagnum is added to the PittMoss®.

Unavailable Water

The unavailable water held in these blends is displayed in Figure 6. Presented are estimates of unavailable water based on the water that remains within the sample when air dry. The range is from about 2.4% in pure PittMoss® to a high of about 4.0% in perlite. Pure sphagnum appears to have about 3.2%. The ratios are proportional due to the methods of determination. Because of the methods used, no interactions can be investigatedー but if any interactions were present, they would be of little importance. It is important to note that PittMoss® releases a little more water per unit volume than either coarse sphagnum or perlite.

Available Water

In this project, only slight differences in the percentages of available water at saturation occur between PittMoss® and coarse sphagnum. These differences are shown in Figure 7. Pure perlite had the lowest available water at 29%. Pure PittMoss® had the greatest at near 67%, and coarse sphagnum had about 62%. The downward slopes in both the Sphagnumperlite and PittMoss®-perlite blends show decreasing available water as perlite increases. The blend of PittMoss® and coarse sphagnum showed a linear and very slight decrease in available water as the percentages of sphagnum increased. As one can see, the available water in PittMoss® is equal to or greater than that of coarse sphagnum, whether alone or in a blend with perlite.

Air Space

Air space values at saturation are displayed in Figure 8. In this study, coarse sphagnum displayed about 9.5% air space. PittMoss® showed about 13.8%. Pure perlite had 25.1% air space at saturation. Additions of the first 12.5% perlite to sphagnum increased air space by about 3.5% to about 13.2% near that of pure PittMoss®. Further additions of perlite to coarse sphagnum had little effect until perlite composed over 50% of the blend. That low level effect was not observed in PittMoss®, perhaps because that level of air porosity was already present in pure PittMoss®. Perlite additions to PittMoss® had no effect on air space until the perlite level was above 62.5%. Interestingly, blends of PittMoss® with coarse sphagnum lost air space, with additions of sphagnum as low as 12.5%. With increased rates of perlite in PittMoss®, air porosity remained at levels close to that of pure sphagnum. These interactions are likely due to a combination of the particle sizes and the pliability of the engineered fibers of PittMoss®. Clearly, PittMoss® has a level of air porosity that is equal to or greater than that of coarse sphagnum. These findings suggest that additions of perlite to PittMoss® are of little value for increasing air porosity. Perlite may add more resilience to the blend and have other values in the blends. It is possible that with additions of PittMoss®, savings may be realized in removing or using less perlite.

Summary

Data from this project shows that when blended with perlite, PittMoss® competes very favorably with coarse sphagnum. PittMoss® has a dry bulk density that is slightly higher than sphagnum but similar to perlite, meaning that it will blend well and have similar blending, shipping, and handling. The particle sizes of PittMoss® are on average larger than a coarse grade of sphagnum, however, the material is more pliable and tends to intermix more readily. Overall, PittMoss® and sphagnum perform about the same in blends. PittMoss® contains lower levels of solids than sphagnum, allowing for more space for air and water. The pliability of PittMoss® appears to yield a slightly greater nesting between particles in a blend than we see with the coarse sphagnum alone. A lower level of unavailable water remains in PittMoss® when dry, likely due to the structure of the fibers. Available water content when saturated is about the same as that in coarse sphagnum, and when blended with perlite, both yield about the same percentages of available water. Air porosity at saturation is a little higher in PittMoss® than in sphagnum, and both are clearly sufficient for crop growth. It appears that perlite added to sphagnum increases air porosity a little more readily than perlite blended with PittMoss®, which may be irrelevant since PittMoss® has sufficient air porosity without added perlite. This survey of physical properties shows that PittMoss® demonstrates properties that make it a good replacement for coarse sphagnum in normal growing media blends.